Locinox only uses premium materials and surface treatments that guarantee years of outdoor use. Which is why Locinox only works with stainless steel and non-ferrous metals. We chrome plate our products and whenever possible, use hot-dip galvanization. Our aluminium lock boxes undergo extensive testing against corrosion.

E-coated aluminium

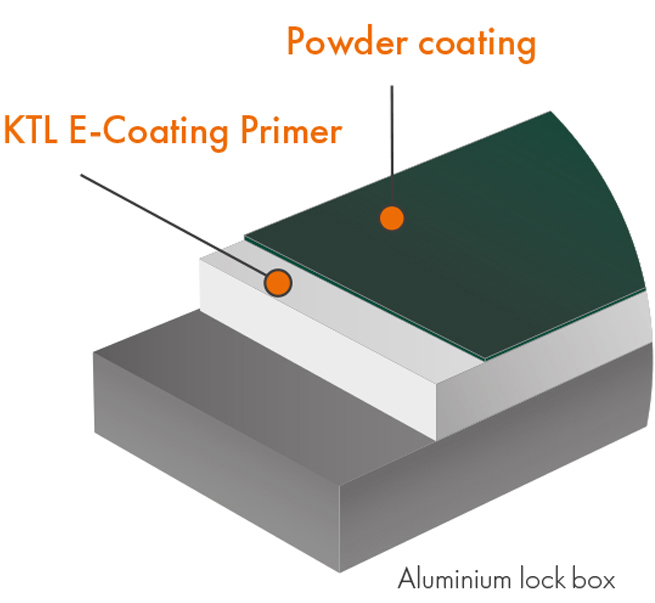

Electrophoretic cathode metal coating, also known as E-coating, is used as a primer on all our aluminium lock boxes. We guarantee a 100% coverage of all the complex and intricate parts. Our lock boxes are electrically charged before being submerged in a bath of oppositely charged paint that adheres to the lock box, offering superior corrosion protection!

The combination of an E-coated surface with a powder coating finish provides one of the best ways to prevent corrosion.

Powder coating

Powder coating is the high-quality finish found on thousands of products we use daily, especially Locinox products!

This protective layer provides a durable finish while remaining attractive. Powder coating reduces the risk of scratches, chipping, abrasions, corrosion, fading and other wear issues. Your product is thus perfectly protected.

Hot-dip galvanization

We use hot-dip galvanization whenever possible.

Our products are dipped into a tank containing molten zinc. They are covered with a 50 µm to 150 µm thick protective layer. This total submersion ensures that every nook and cranny is covered with a protective coating.

Deutsch

Deutsch

Español

Español

Français

Français

Nederlands

Nederlands

Polski

Polski

Русский

Русский